Forskjell mellom versjoner av «Band saw English»

(→Before using the bandsaw) |

(→References) |

||

| (5 mellomliggende revisjoner av samme bruker vises ikke) | |||

| Linje 8: | Linje 8: | ||

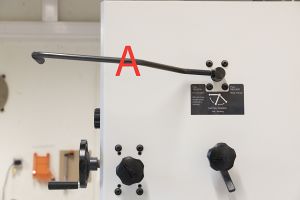

[[Fil:Posisjon for hendel til bladspenning.jpg|miniatyr|Figure 1 - Lever A must always be in a horizontal position when using the bandsaw (Full tension)..]] | [[Fil:Posisjon for hendel til bladspenning.jpg|miniatyr|Figure 1 - Lever A must always be in a horizontal position when using the bandsaw (Full tension)..]] | ||

[[Fil:Båndsag bladspenning innstilling.jpg|miniatyr|Figure 2 - Bandsaw blade tension scale and blade tension handwheel..]] | [[Fil:Båndsag bladspenning innstilling.jpg|miniatyr|Figure 2 - Bandsaw blade tension scale and blade tension handwheel..]] | ||

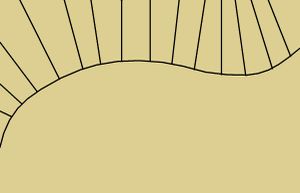

| − | [[Fil:Bandsaw blade tension scale. | + | [[Fil:Bandsaw blade tension scale.JPG|miniatyr|Figure 3 - Bandsaw blade tension scale set for 13 mm blade..]] |

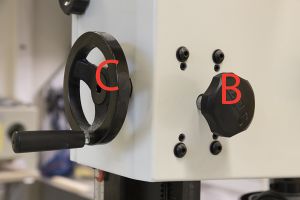

[[Fil:Stille bladstyringens høyde.jpg|miniatyr|Figure 4: Adjust height of blade guide by using locking knoB B and wheel C.]] | [[Fil:Stille bladstyringens høyde.jpg|miniatyr|Figure 4: Adjust height of blade guide by using locking knoB B and wheel C.]] | ||

[[Fil:AV- og på-knapper.jpg|miniatyr|Figure 5: On and off buttons.]] | [[Fil:AV- og på-knapper.jpg|miniatyr|Figure 5: On and off buttons.]] | ||

| Linje 26: | Linje 26: | ||

Lever A (Figure 1) at the back of the band saw must always be in a horizontal position when the saw is in use. Then the saw blade will be under tension.<br> | Lever A (Figure 1) at the back of the band saw must always be in a horizontal position when the saw is in use. Then the saw blade will be under tension.<br> | ||

| − | Check if the red needle shows the correct blade tension for the blade mounted on the saw. Turn the blade tension handwheel to adjust if necessary (Figure 2 and 3). | + | Check if the red blade tension needle shows the correct blade tension for the blade mounted on the saw. Turn the blade tension handwheel to adjust if necessary (Figure 2 and 3). |

The bandsaw is will usually be fitted with a blade which is 13mm wide with 4 TPI (teeth per inch)).<br> | The bandsaw is will usually be fitted with a blade which is 13mm wide with 4 TPI (teeth per inch)).<br> | ||

| Linje 59: | Linje 59: | ||

- fault in the blade welding joint<br> | - fault in the blade welding joint<br> | ||

| − | Should the machine start making strange noises - stand back and press the red stop button (Figure | + | Should the machine start making strange noises - stand back and press the red stop button (Figure 5).<br> |

Small pieces of wood are removed from the saw table after the saw blade has stopped – '''not before'''!<br> | Small pieces of wood are removed from the saw table after the saw blade has stopped – '''not before'''!<br> | ||

| − | ===Adjust angle | + | ===Adjust angle of the saw table=== |

Disconnect the power from the band saw.<br> | Disconnect the power from the band saw.<br> | ||

| − | Release locking lever D (Figure | + | Release locking lever D (Figure 6). The saw table can be tilted up to 45 degrees towards the right seen from the front. Tighten locking lever D when you have the angle you want.<br> |

Remember to return the saw table to the horizontal position when you are finished.<br> | Remember to return the saw table to the horizontal position when you are finished.<br> | ||

===Position on fence and rail=== | ===Position on fence and rail=== | ||

| − | The fence can stand upright or lie flat on the saw table. Use the screw knobs E (Figure | + | The fence can stand upright or lie flat on the saw table. Use the screw knobs E (Figure 7 and 8) to loosen and fasten the fence.<br> |

===Fine-tuning of fence position=== | ===Fine-tuning of fence position=== | ||

| − | Loosen the fencevwith locking knob F and small knob G under the rail (Figure | + | Loosen the fencevwith locking knob F and small knob G under the rail (Figure 9). Push the fence to the approximately desired position and lock it to the rail with small knob G. Fine-tune with millimeter wheel H and lock with locking knob F.<br> |

===Straight cuts=== | ===Straight cuts=== | ||

| Linje 78: | Linje 78: | ||

===Curved cuts=== | ===Curved cuts=== | ||

| − | DO NOT force the tool to do something it cannot do. When the regular saw blade that is mounted on the saw, you cannot saw arcs where the "approximately straight" area is less than 1.5 cm. Arches must then be sawn in segments with relief cuts from the side towards the arch as shown (Figure | + | DO NOT force the tool to do something it cannot do. When the regular saw blade that is mounted on the saw, you cannot saw arcs where the "approximately straight" area is less than 1.5 cm. Arches must then be sawn in segments with relief cuts from the side towards the arch as shown (Figure 10).<br> |

Can't be said too often: Gloves and loose (sleeves on) clothing should absolutely not be used on any rotating tool – band saw included!<br> | Can't be said too often: Gloves and loose (sleeves on) clothing should absolutely not be used on any rotating tool – band saw included!<br> | ||

| Linje 90: | Linje 90: | ||

Before you start the saw, set the blade guide to the correct height for the job you're going to do.<br> | Before you start the saw, set the blade guide to the correct height for the job you're going to do.<br> | ||

| − | You do this by loosening lock knob B (Figure | + | You do this by loosening lock knob B (Figure 4). You then adjust the blade guide to the correct height for what you are going to saw by turning the wheel C. Lock the blade guide by turning the locking knob B.<br> |

For straight cuts, the blade guard should be as close to the workpiece as possible, approx. 2.5 cm above the workpiece.<br> | For straight cuts, the blade guard should be as close to the workpiece as possible, approx. 2.5 cm above the workpiece.<br> | ||

| Linje 104: | Linje 104: | ||

Turn on the vacuum cleaner.<br> | Turn on the vacuum cleaner.<br> | ||

| − | Start the saw by holding the green on button for ½ second (Figure | + | Start the saw by holding the green on button for ½ second (Figure 5). |

===Practical exercise=== | ===Practical exercise=== | ||

Find a piece of wood and try a couple of cuts on the saw!<br> | Find a piece of wood and try a couple of cuts on the saw!<br> | ||

| − | Small pieces on the saw table: Stop the machine BEFORE you remove them!<br> | + | Small pieces on the saw table: Stop the machine '''BEFORE''' you remove them!<br> |

Burn marks in thin panels: Could be a problem with a worn saw blade!<br> | Burn marks in thin panels: Could be a problem with a worn saw blade!<br> | ||

| Linje 123: | Linje 123: | ||

== References == | == References == | ||

<references/> | <references/> | ||

| + | |||

| + | [[Fil:Manual-JWBS-18SFXBandSaw UM EN ED4 1.pdf|miniatyr|Manual for Bitrafs bandsaw.]]<br> | ||

[[Category:Utstyr]] | [[Category:Utstyr]] | ||

Nåværende revisjon fra 8. mai 2025 kl. 11:53

Innhold

Basic bandsaw usage

Safety an general usage

Before using the bandsaw

Never connect power to a machine before you have made a preliminary check everything is in order with the machine.

Always write in Bitraf's calendar: name, tool (Bandsaw), phone number, date and time from and until which you will use the tool. Access to the calendar and how it is used can be found here: [[1]].

- Check inside the saw if the person using the bandsaw before you has cleaned it after usie, if not clean before you start.

- Connect vacuum cleaner to saw.

- Check if the blade is sharp - feel with a finger - if the blade is dull - stop work.

Lever A (Figure 1) at the back of the band saw must always be in a horizontal position when the saw is in use. Then the saw blade will be under tension.

Check if the red blade tension needle shows the correct blade tension for the blade mounted on the saw. Turn the blade tension handwheel to adjust if necessary (Figure 2 and 3).

The bandsaw is will usually be fitted with a blade which is 13mm wide with 4 TPI (teeth per inch)).

With the saw blade that is usually found on the band saw, you should only cut wood and plastic materials. It is not recommended to rip thick boards with this blade.

Check out key # 6 to unlock the band saw if everything is in order.

Safety and usage

Do not use any machines at Bitraf if you are tired or under the influence of alcohol or other drugs.

Never walk away from a running machine without supervision.

Remove ties, scarves, rings, watches and other jewelery before using the band saw. Also put up long hair.

Always keep fingers (and other body parts, including hair and beard) outside the black circle around the saw blade.

Gloves, loose sleeves and loose clothing should not be used when working with rotating tools – including bandsaws!

Use a dust mask, safety glasses and hearing protection! Tinnitus, damaged hearing and damaged vision are not cool!

Fine dust particles that you breathe in can cause discomfort and an increased risk of cancer and lung diseases.

Use a push stick and/or push block when cutting small or narrow workpieces!

Be concentrated on the work, not on other things when using machines. If you are going to talk to others, turn off the saw.

Do not work with the wood upright or in any other unusual positions without support. Round objects and other materials that do not lie flat against the saw table and/or fence must be attached to other materials with screws or clamps for stability!

Bandsaw blades are subjected to high stresses and breakage are sometimes unavoidable. Some common causes of blade breakage are:

- you use a too wide blade to cut a curve with a small radius

- you use too much force to guide the workpiece towards the blade - instead, let the blade work through the material without using force

- upper blade guide too high above the work piece

- blunt or uncorrectly set saw blade teeth

- incorrectly adjusted blade guides

- too high blade tension

- fault in the blade welding joint

Should the machine start making strange noises - stand back and press the red stop button (Figure 5).

Small pieces of wood are removed from the saw table after the saw blade has stopped – not before!

Adjust angle of the saw table

Disconnect the power from the band saw.

Release locking lever D (Figure 6). The saw table can be tilted up to 45 degrees towards the right seen from the front. Tighten locking lever D when you have the angle you want.

Remember to return the saw table to the horizontal position when you are finished.

Position on fence and rail

The fence can stand upright or lie flat on the saw table. Use the screw knobs E (Figure 7 and 8) to loosen and fasten the fence.

Fine-tuning of fence position

Loosen the fencevwith locking knob F and small knob G under the rail (Figure 9). Push the fence to the approximately desired position and lock it to the rail with small knob G. Fine-tune with millimeter wheel H and lock with locking knob F.

Straight cuts

Feed the workpiece straight ahead, possibly by using the fence as a sideways support.

Curved cuts

DO NOT force the tool to do something it cannot do. When the regular saw blade that is mounted on the saw, you cannot saw arcs where the "approximately straight" area is less than 1.5 cm. Arches must then be sawn in segments with relief cuts from the side towards the arch as shown (Figure 10).

Can't be said too often: Gloves and loose (sleeves on) clothing should absolutely not be used on any rotating tool – band saw included!

Some things to be aware of:

Thick or tall materials put extra wear and tear on the saw blade - write a message on the Woodwork channel on Slack or to someone responsible for the tool so we can check if it needs to be replaced!

Since the blade on the band saw moves down towards the saw table, the general risk of kickback is small compared to table saws. BUT: you still have to be careful with round objects, refer to what is written in the "Safety and use" section about working with the material upright or in unusual positions without support.

Adjust the upper blade guide to the correct height

Before you start the saw, set the blade guide to the correct height for the job you're going to do.

You do this by loosening lock knob B (Figure 4). You then adjust the blade guide to the correct height for what you are going to saw by turning the wheel C. Lock the blade guide by turning the locking knob B.

For straight cuts, the blade guard should be as close to the workpiece as possible, approx. 2.5 cm above the workpiece.

If you need to cut curves, the blade guard can be raised. With the blade guard 10-15 cm above the workpiece, you can have a good view of what you're dooing.

The purpose of the protective housing on the saw blade is to protect the user and to stabilize the saw blade laterally.

When these checks have been completed, you are "good to go"!

Connect power to band saw.

Connect a vacuum cleaner if you haven't already.

Turn on the vacuum cleaner.

Start the saw by holding the green on button for ½ second (Figure 5).

Practical exercise

Find a piece of wood and try a couple of cuts on the saw!

Small pieces on the saw table: Stop the machine BEFORE you remove them!

Burn marks in thin panels: Could be a problem with a worn saw blade!

When finished using the band saw

Unplug the power to the band saw and put the lock on the plug.

Always clean the tool and the floor around after you! Open and clean inside the saw. Use compressed air in places that are difficult to access, and vacuum cleaner where you reach. Clean the saw blade if there is a lot of dirt on it. Then the person using the saw after you're finished doesn't have to spend their time cleaning up after you - this contributes to a healthy environment at Bitraf! Remember the "do-o-cracy" at Bitraf!

If someone has forgotten to clean - clean up after them too, since this contributes to Bitraf beeing a nice place to come - and people perhaps also to treat our equipment better.

Finish off by checking in the key.